So after some diligent head replacing, tuning and retuning of the snare I still have a dreaded resonant snare buzz. I really wouldn’t think much of it since it is a natural phenomenon but it is really loud and long and messing with the mix, more than I like when I hit the nearby toms. My original idea of changing the heads and replacing the snare wires actually made it worse. I have tried varying head tuning tensions and wire placements between the throw off and the butt plate. Nothing has seemed to work.

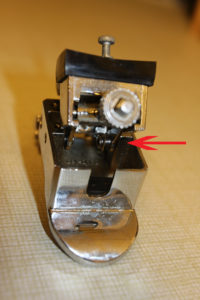

On my last attempt to refine the snare sound I flipped the throw-off down and wasn’t able to get it back to the locked position. A closer look I noticed that the rivet on the pivot of the cantilever had fallen out. It is retained by a set screw that, I thought, managed to back out. This was causing the throw off attachment to the nylon snare cord to skew some, I think causing the snare wires to be canted some and buzz more. I tried to work some magic on the screw but I was unable to get it seated strong enough to hold the rivet. Probably due to the age. I was very blessed to have been able to purchase the DW Drum Set in 1999 and it has been a wonderful kit for me. That has been a while ago and things age, especially parts that move and hold tension.

So, instead of further aggravation with the throw-off, DW MAG Throw Off with 3-Position Butt Plate and it is awesome. After watching a few videos I decided to give it a shot and order it through Clark’s Music Center. Wow, what a difference time and technology improvements make. Through my research I contacted DW directly and they recommended this for the upgrade as it would fit my snare without any further drilling. And they were correct. The install was quite easy and with head removal only took about 15 minutes. I decided to remove both heads again to address some tightness in the tension lugs as well. I plan to add a tiny amount of lithium grease on them to smooth up the action. They have seemed to get tighter over the years as well.

So, instead of further aggravation with the throw-off, DW MAG Throw Off with 3-Position Butt Plate and it is awesome. After watching a few videos I decided to give it a shot and order it through Clark’s Music Center. Wow, what a difference time and technology improvements make. Through my research I contacted DW directly and they recommended this for the upgrade as it would fit my snare without any further drilling. And they were correct. The install was quite easy and with head removal only took about 15 minutes. I decided to remove both heads again to address some tightness in the tension lugs as well. I plan to add a tiny amount of lithium grease on them to smooth up the action. They have seemed to get tighter over the years as well.

I also wanted to take time to address the tightness of the tension rods when using them on the snare. I let the drum room get too moist (snicker) a few years ago before I started using a dehumidifier and it wreaked havoc on some of the parts of my drums. Especially those on the snare where I tend to sweat near. I noticed the rod washers were also rough feeling and might have a tiny bit of rust. I am soaking them in a CLR and water solution to help reduce some of the buildup. I then plan to lightly brush them with a wire wheel and then add a very light film of lithium grease to them. I did searching on what people are using and it ranged from 3 and 1 0il to Vaseline to olive oil. Tasty…

I have used lithium grease in the past when working on our cars and I think a light film of this will add the necessary lubrication without all of the buildup and dust attraction. It goes on wet at first but dries to a more talc like feel.

Again my drumming recording adventure is continuing and always a learning process for me, even after all of the years I have been around the drums. I hope to have this kit situated firmly soon so all I have to do is hit the room, turn on the equipment and play.

I also have made a decision on my MXL Drum Cube Tom Mics and will post about that soon. I may be straying in brand for them. Stay tuned…

Keep on drumming.